The Oenoflow PRO XL system introduces Pall’s new Optimizer algorithm which automatically adjusts system settings in real time based on the wine’s individual physical and chemical characteristics. With this highly enhanced performance, wineries with the new Oenoflow PRO XL system have seen an estimated 10% savings in OPEX when compared to traditional crossflow systems.

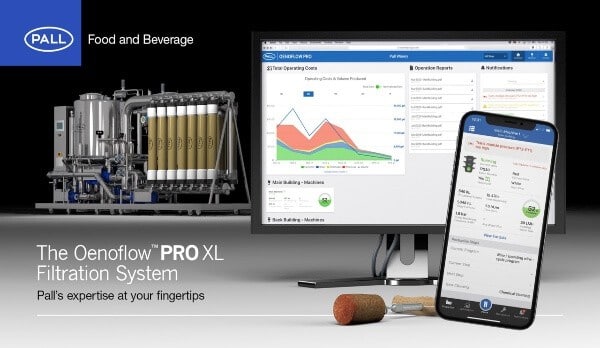

- Executives/managers can track OPEX for each system, each winery or for the entire winery group as needed. The Oenoflow PRO XL system simplifies operations by aggregating data from each machine into a customer specific dashboard.

- Production supervisors can access data in the dashboard and download reports showing the filtration history of each machine, including rinse verification recorded by the included conductivity meter.

- Operators can use the new Oenoflow PRO mobile or desktop app to view live production status, volume remaining to be filtered and alarms.

- Maintenance personnel can use the new Oenoflow PRO mobile or desktop app to access manuals, spare parts lists, service records and even request a service visit from Pall technicians.

Explore the Oenoflow PRO XL system here.

For more information, contact: foodandbeverage@pall.com.