The biggest misconception of Artificial Intelligence (AI) is that it is an abstract, futuristic concept. High-value, low-risk AI applications can be applied to boost OEE, maximise production quality and empower workers.

AI is a crucial piece of the factory of the future. Connecting the manufacturing process through an end-to-end connected factory provides unlimited production data that humans simply cannot fully compute.

Let’s talk about the real, shop-floor benefits of integrating AI today.

Benefits AI & ML in today’s manufacturing:

Machine Learning, as an element of AI, provides automated insights that either take humans a long time to do – or that humans simply cannot spot. From shop-floor diagnostics to extremely accurate predictive production capabilities, automation that harnesses the power of Machine Learning will propel your Factory to the Future.

Insights derived from AI through Machine Learning can be applied to each process step, boosting human-machine interaction. These insights solve both chronic issues, which are ongoing and have a lower level impact on performance, and sporadic problems, those momentary changes or faults that cause performance issues. READ MORE >

Today, one of the leading use cases for Machine Learning is to identify production issues faster. Initially, we may need humans to act on this data to bring performance back into line, but over time we want to leverage machine learning to deploy an automated process (i.e robots or drones) to make the required adaptation or fix.

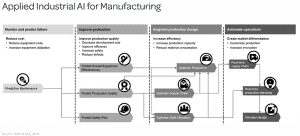

Machine Learning applications:

Defect Detection: Recognise production defects like scratches, dents, low fill levels, and leaks. It will also help with the reduction of false positives as the machine can learn to spot small variances within tolerance to an exceptionally high degree of certainty.

Preventative Maintenance: Technicians and engineers undoubtedly rely on operational data as well as their experience and tacit knowledge to design maintenance schedules. Machine Learning can help detect trends that teams can use to perform maintenance on equipment exactly when it needs it, eliminating failure while minimising excess labour for technicians.

Digital Twins: Use real data to run extremely accurate simulations to model process changes, upgrades, or new equipment. Machine Learning facilitates data computation across a factory’s processes to mimic the entire production line or sections throughout the process. Instead of running real experiments, data derived from machine learning produces near-perfect simulations which can be optimised and adjusted before starting real-world trials.

Quality Assurance: Machine Learning over hours of production output can pick up and self-learn trends throughout the manufacturing process. Before a product shifts too far from accepted standards, automation can intervene and self-correct.

Practical AI applications:

The use of AI is quickly evolving in manufacturing, and exactly how AI and Machine Learning will all come together in the factory of the future is an ongoing industry-wide project.

LineView is currently working on several Artificial Intelligence proof of concepts, such as these, to suggest potential actions, guided interventions and forecasts for better outcomes:

- Task/SIC Review and Resource Allocation

- Accurate Production Planning

- Tackling Abnormal Machine Behaviour