Hygienic sealing portfolio for the process industry

Freudenberg Sealing Technologies is expanding its sealing portfolio for hygienic systems in the process industry to include two new products: Hygienic Forseal and Hygienic Pressure Seal. Both are specially developed for food applications that experience high pressures and temperatures. The unique combination of high-performance elastomers (EPDM or Fluoroprene® XP) and premium PTFE materials (Quantum®) also makes the seals resistant to a wide range of aggressive media.

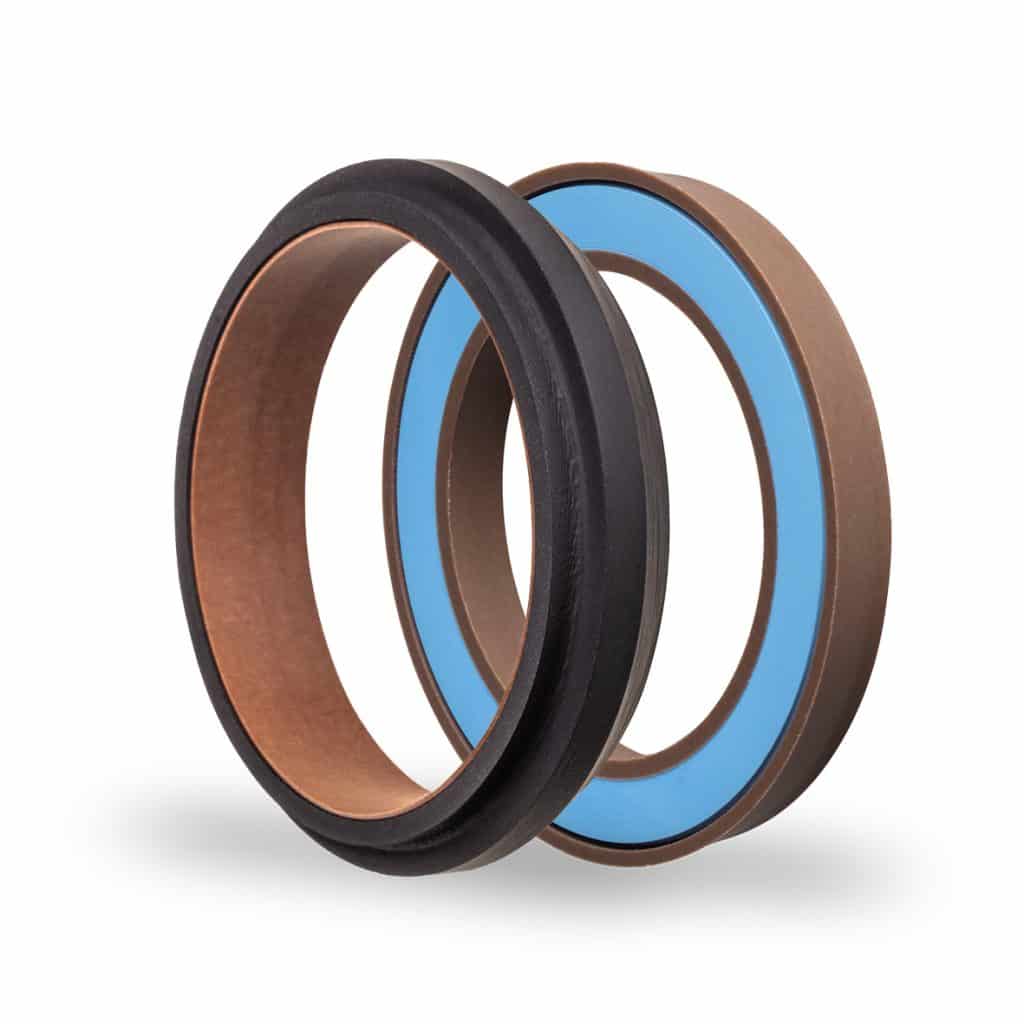

Based on the proven Forseal from Freudenberg Sealing Technologies, the new hygienic version features a design that has been adapted to the extreme conditions and requirements of the food industry. While the classic version of the Forseal uses a steel spring to ensure contact pressure, the hygienic solution uses an elastomer ring. In addition, the Hygienic Forseal offers a flat surface to the product medium and has no undercuts whatsoever in terms of hygiene. The assembly is possible in an undivided installation space. The high-performance, low-wear Quantum® PTFE used also has the usual industry-specific approvals for food and beverage applications, in contrast to the standard material of the proven Forseal. Double seals, anti-rotation devices and many other

customized adaptations are possible.

The Hygienic Pressure Seal can be used as a rod seal in valves or pumps, for example. The contact element consists of the highperformance Quantum® PTFE combined with an elastomeric pressure

ring. It complies with the same high hygiene standards as the classic version, but offers improved performance: very good pressure resistance up to 150 bar, excellent friction values, an extended service life and a design without dead space. Furthermore, it has good dry running properties. Customer-specific adaptations are possible if required. For example, a steel carrier ring can be added for support or an additional dust lip.

The Hygienic Pressure Seal and Hygienic Forseal from Freudenberg Sealing Technologies enable customers to achieve the highest standards of purity. Flat contact surfaces with the process medium

successfully prevent dead spaces. The high-performance materials are also resistant to aggressive cleaning agents and thus enable a cleaning process in the CIP/SIP procedure. With the help of customer-specific adaptation options, both products can be optimally tailored to the respective application.

Freudenberg Sealing Technologies’ comprehensive sealing portfolio for hygienic process plants includes a wide range of other food-compliant and dead space-free sealing solutions. Examples include the Hygienic Usit® to prevent the formation of germs under screw heads and the

Radiamatic® HTS II 9539 VL, a radial shaft seal with a pre-set sealing lip specially developed for the process industry. The experts at Freudenberg are constantly developing innovative new products and materials in line with the motto “Innovating Together” to meet the ever-increasing demands placed on hygienic seals and to offer customers the best possible solution. The two new products, Hygienic Forseal and Hygienic Pressure Seal, have also been developed this way.

Click here for more information

Freudenberg Sealing Technologies

Watch Freudenberg’s Corporate Movie Here